DCFusor

Yellow Jacket

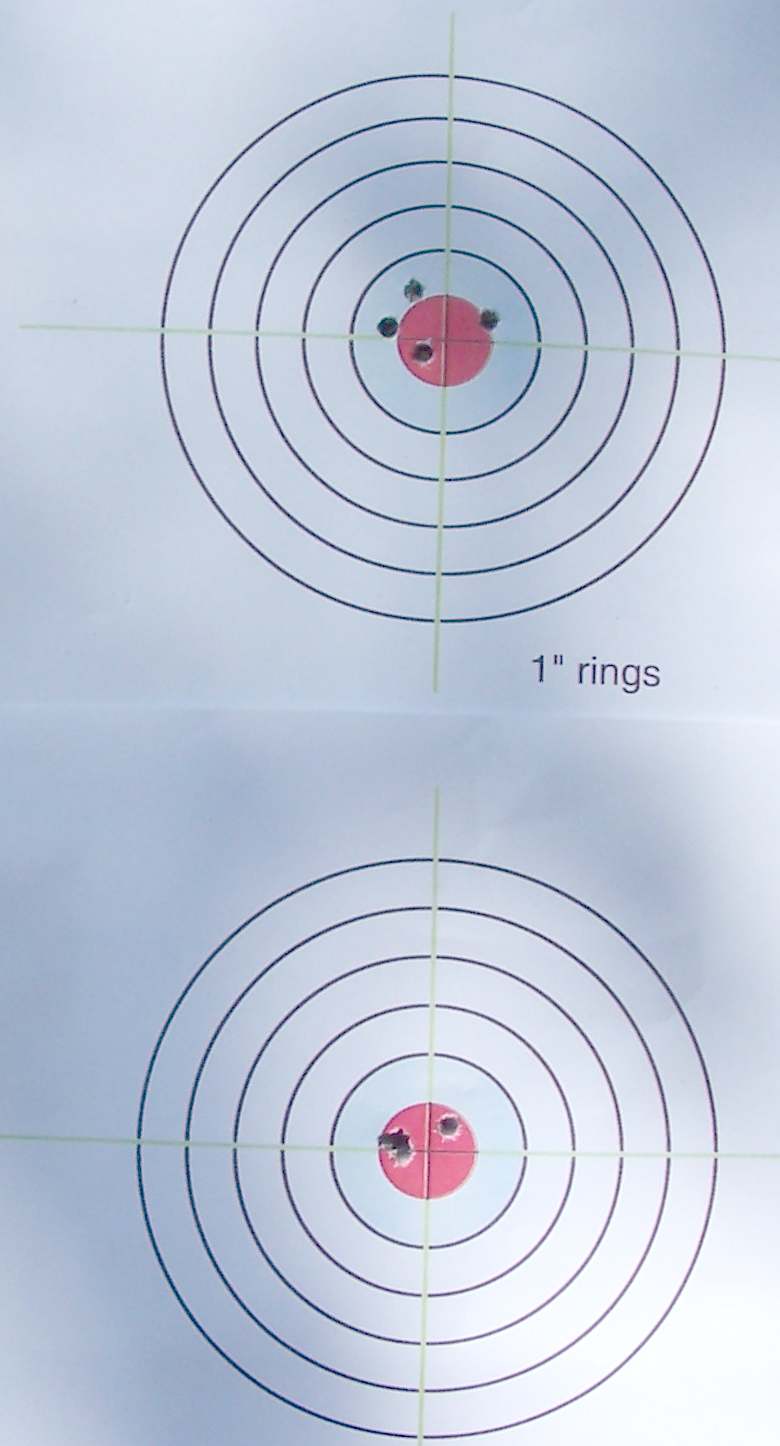

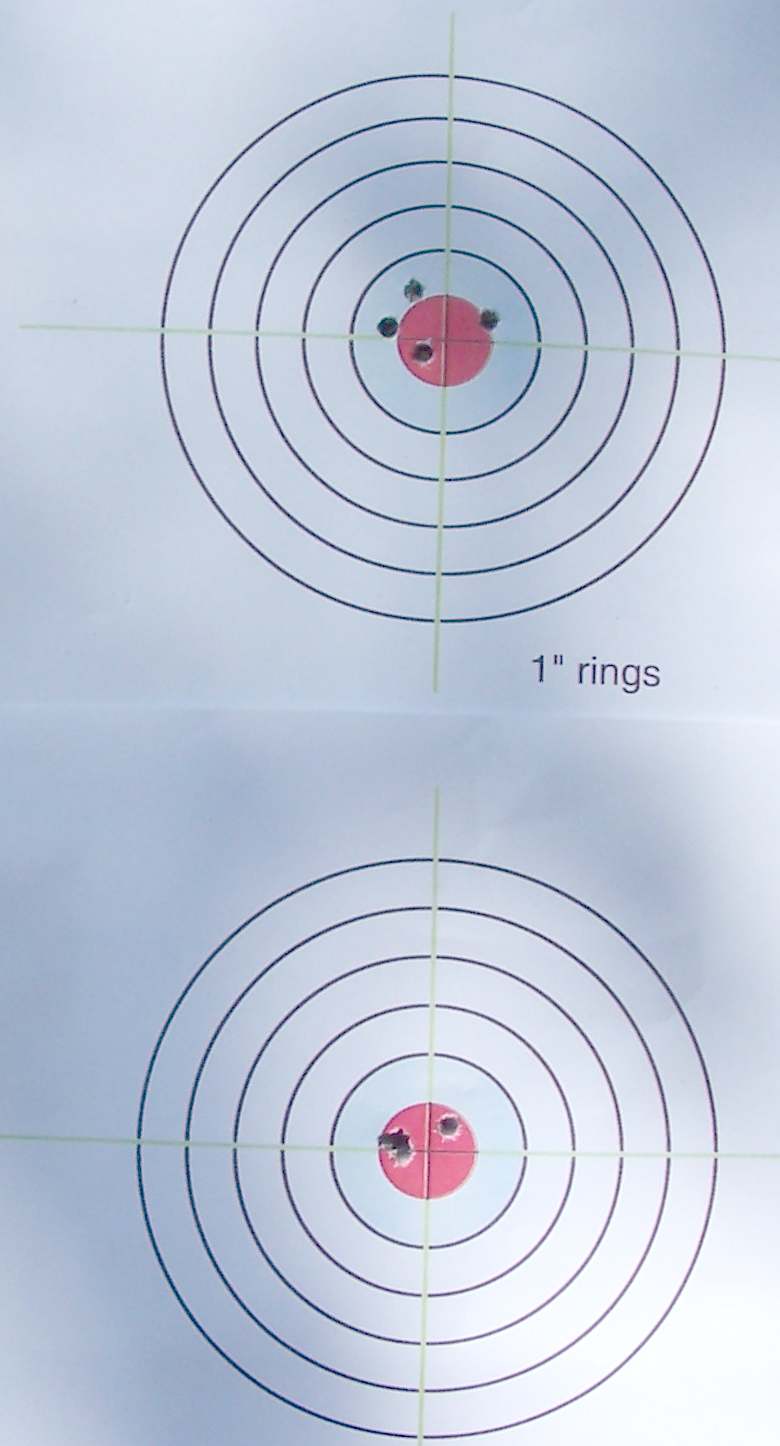

I've been playing with a Howa in .204 a friend asked me to "breath on" a little. Here are the results, with before and after targets @ 60 yds (my front yard range I use for quick tests).

Upper target is 4 shots of hornady factory ammo "before".

Lower target is 4 shots same ammo "after".

I could do more with this one - I can more often than not put them all in the same hole with guns I've really worked on (and that have better scopes), but this is what it is. Funny, you just don't need a hell of a lot of firepower when you can really put each one right where it belongs.

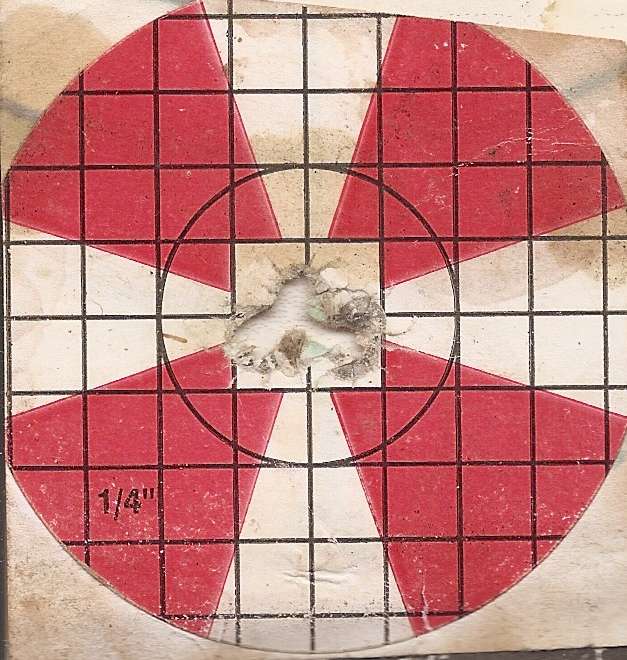

This ammo gets 4250 fps out of the gun...it's varmint bullets but at this speed they have no trouble at all going through 3/8" steel, making a half inch hole more or less. They "explode" but go on through anyway.

This ain't bad for factory ammo, cold barrel at first (the shot tossed to the right was the first in each case, hmmm). Now, precision reloading and a better scope and I'd bet this would do one holers at 200 yds, if I finish the barrel lapping job - I only "touched" a rough spot I felt, and didn't get it really done. The other thing - factory trigger really stank, so I re-stoned the sear engagement surfaces and put on the magic grease to make it break nicely - before, it was "grinchy" and you couldn't hold on target through all the ick-ick-ick till it went bang.

Not too shabby for a cheap gun, though. Note, I typically don't set the scope for "dead on" for these tests, as it becomes hard to shoot a good group when you destroy the aimpoint.

Upper target is 4 shots of hornady factory ammo "before".

Lower target is 4 shots same ammo "after".

I could do more with this one - I can more often than not put them all in the same hole with guns I've really worked on (and that have better scopes), but this is what it is. Funny, you just don't need a hell of a lot of firepower when you can really put each one right where it belongs.

This ammo gets 4250 fps out of the gun...it's varmint bullets but at this speed they have no trouble at all going through 3/8" steel, making a half inch hole more or less. They "explode" but go on through anyway.

This ain't bad for factory ammo, cold barrel at first (the shot tossed to the right was the first in each case, hmmm). Now, precision reloading and a better scope and I'd bet this would do one holers at 200 yds, if I finish the barrel lapping job - I only "touched" a rough spot I felt, and didn't get it really done. The other thing - factory trigger really stank, so I re-stoned the sear engagement surfaces and put on the magic grease to make it break nicely - before, it was "grinchy" and you couldn't hold on target through all the ick-ick-ick till it went bang.

Not too shabby for a cheap gun, though. Note, I typically don't set the scope for "dead on" for these tests, as it becomes hard to shoot a good group when you destroy the aimpoint.