- Messages

- 5,009

- Reaction score

- 5,037

- Points

- 308

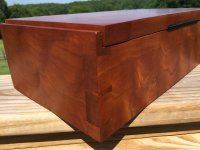

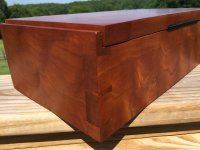

A while back, I purchased a bunch of 8" wide cherry boards for a large CD tower project I was doing. They come rough cut, 4/4, and so you never really know exactly what you are getting until you feed them through the planer. Well, I was running them through the planer and this highly figured board appeared. Curly cherry. I pulled it out of the pile and set it aside. I knew that it was far too good to end up as just another shelf that would never be seen.

So I made this box. 12-1/2" x 6-3/4" x 4". Hand cut dovetails, Brusso hinges machined from solid brass stock, sliding tray, ebony lift, oil and wax finish. The figure is amazing and quite 3D. It moves and shimmers as your perspective changes.

So I made this box. 12-1/2" x 6-3/4" x 4". Hand cut dovetails, Brusso hinges machined from solid brass stock, sliding tray, ebony lift, oil and wax finish. The figure is amazing and quite 3D. It moves and shimmers as your perspective changes.