John Carroll explains how to read that obscure scale hidden in plain sight on the tongue of your framing square.

www.jlconline.com

JLC Online

Training the Trades

Framing Square Basics: Octagon Layout

By John Carroll

DOWNLOAD THE PDF VERSION OF THIS ARTICLE. (367.79 KB)

Not too many octagonal—or eight-sided—houses are built these days, but for a brief period of time between 1850 and 1870, this was a popular architectural style; early Quakers in southeastern Pennsylvania are known to have built octagonal stone school buildings as early as 1760. Nowadays, if you are asked to frame an octagonal structure, it will most likely be a gazebo or a cupola, or perhaps a turret-style addition. You may also be asked to install an octagonal window and so would need to know how to frame the rough opening.

Carpenters have called the octagon “the poor man’s circle” because it approximates the shape of a circle without the problems of bending wood or cutting glass along curved lines. The cuts required to build an octagon are simple cuts, consisting of 90-, 45-, and the occasional 22 1/2-degree angles. So, once you get the layout completed, the building process is straightforward.

The layout of an octagon, on the other hand, is a bit more involved. It is certainly more challenging than laying out a circle or a rectangle, but it’s not as complex as it might seem at first glance. As I’ll show here, you can use a framing square to lay out an octagon up to 67 inches wide without doing any math at all, and to lay out larger octagons using only one simple multiplication computation.

Octagon scale. On the tongue of a traditional framing square are a series of lines, dots, and numbers, all of which have bewildered generations of carpenters. Although it is by no means apparent, those symbols make up the octagon scale.

The scale is made up of 67 equally spaced increments. (Some newer squares have only 65 increments because the manufacturer has used the space historically occupied by the last two dots to label the mysterious scale with the words “octagon scale.”) Most of the increments are marked with a dot. But every fifth increment is marked with a vertical line and a number; that’s how the increments numbered 5, 10, 15, 20, and so forth are represented. The increments are 0.2071 inch long, which is exactly one-half the length of the side of an octagon that is 1 inch wide. As you’ll see, for every inch of width of the octagon being laid out, one of these increments will be required.

Click to enlarge

Along with various other scales and tables, a standard framing square also includes a useful octagon scale on the tongue of the square. The scale shown here consists of 65 0.2071-inch-long increments, a measurement that is equal to one-half the width of one of the sides of an octagon that is 1 inch wide. As shown in the drawing, the ratio of the width of an octagon to the length of one of its sides is 1 to 0.4142.

Along with various other scales and tables, a standard framing square also includes a useful octagon scale on the tongue of the square. The scale shown here consists of 65 0.2071-inch-long increments, a measurement that is equal to one-half the width of one of the sides of an octagon that is 1 inch wide. As shown in the drawing, the ratio of the width of an octagon to the length of one of its sides is 1 to 0.4142.

Math-free layout. To see how this works, let’s say you need to frame an octagonal rough opening that’s 31 inches wide for a 30‑inch octagonal window. Begin by framing a square opening that’s 31 inches by 31 inches. Now, find and mark the center of each side. From each center point, measure and mark in both directions a distance that’s equal to 31 increments on the octagon scale.

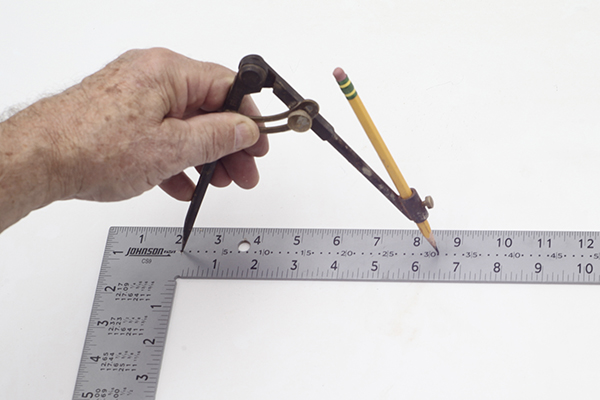

I like to use my divider for this task. I place one leg of the divider at the first line at the beginning of the scale and the other at the dot representing 31. I lock the divider at this setting, then use it to step out and mark in both directions from the center marks on the four sides of the window opening. These marks represent the eight corners of the 31-inch octagon. All that remains is to measure, cut, and install the four diagonal pieces.

Click to enlarge

To lay out a 31-inch-wide rough opening for an octagonal window, the legs of a divider have been set to the “31” increment on the octagon scale, which measures 6 7/16 inches.

To lay out a 31-inch-wide rough opening for an octagonal window, the legs of a divider have been set to the “31” increment on the octagon scale, which measures 6 7/16 inches.

Click to enlarge

The divider is then used to mark the corners of the octagon within the 31-inch-wide rough opening, as shown above. Each side of the octagon measures 12 7/8 inches.

The divider is then used to mark the corners of the octagon within the 31-inch-wide rough opening, as shown above. Each side of the octagon measures 12 7/8 inches.

The divider, of course, is not essential. You can use a tape measure, a ruler, or just a strip of wood to take and transfer the measurement. The measurement you need to step out from the center point, by the way, is a hair shy of 6 7/16 inches. And the length of each side—and also of the diagonal pieces—is double that, which is 12 7/8 inches.

You can use the octagon scale to lay out octagons larger than 67 inches, but it’s easier to use math. If you need to lay out a 12‑foot (144-inch) octagon, for example, you could set a divider to 48 on the scale and then step it out three times from the centerline to lay out the 144 octagon-scale increments. But as shown in the example above, it would be easier to simply multiply 144 by .2071 to find the dimension needed in inches. That dimension, by the way, is 29.82, or 29 13/16, inches.

Click to enlarge

For octagons larger than 67 inches, find the length of one-half of one of its sides by multiplying its width by 0.2071. For a 12-foot-wide octagon, for example, that dimension is 29 13/16 inches. Each side of the octagon will measure 59 5/8 inches.

For octagons larger than 67 inches, find the length of one-half of one of its sides by multiplying its width by 0.2071. For a 12-foot-wide octagon, for example, that dimension is 29 13/16 inches. Each side of the octagon will measure 59 5/8 inches.

Photos by Mathew Navey; illustrations by Tim Healey.

About the Author

John Carroll

John Carroll, author of Working Alone, is a builder who lives and works in Durham, N.C.